PUR

ClarityCap® has taken the science behind audio performance and capacitor technology seriously, for many years. During that time research has been carried out with the leading academic audio research departments and respected audio industry figures, launching new products, only when we are able to contribute tangible benefits.

The development of the Purity audio capacitor builds on the ClarityCap® experience of working closely with the specialists in the audio industry, to design and manufacture metallised polypropylene film capacitors tailored for use in audio applications.

Taking inspiration from the highly regarded CSA and CMR range, the Purity™ (PUR) range employs the same carefully researched micro-phonics reducing processing parameters. CopperConnect® technology enables designs to employ narrower films for reduced capacitor ESR without introducing the corollary increase in end connection impedance. The philosophy of eliminating as many boundaries as possible is extended in the use of a silver-coated, multi-strand Van den Hul® cable, often specified by loudspeaker manufacturers.

|

ClarityCap introduced CopperConnect technology on the CMR and CSA families, addressing a previously overlooked area of audio capacitor performance. Dielectric, electrode and lead-wire materials have all been extensively optimised over the years, however, connection of capacitor electrodes to the leads has always relied on a thermal arc spray of tin-zinc. This process results in hundreds of thousands of oxidised grain boundaries, which can introduce distortion and phase-shifts at boundary crossings while also increasing propagation impedance with diameter. Including the CopperConnect lattice at the end connection dramatically reduces the number of grain boundary crossings facing the audio signal. By increasing the thickness of CopperConnect to 10mm, Purity opens up a wider channel for the audio-signal to flow through – setting a new standard of performance for audio capacitors. In early listening-tests, Audio Engineers have commented that Purity provides a significantly lower noise floor, with more ‘dark space’ around the audio signal, and an improved dynamic range. These features provide greater clarity in reproduction of sound as well as improved spatial separation of individual instruments and vocals. We are confident you’ll agree that ClarityCap's commitment to innovation has once again raised the bar for audiophile capacitor performance! |

|

PUR Size-Chart 1

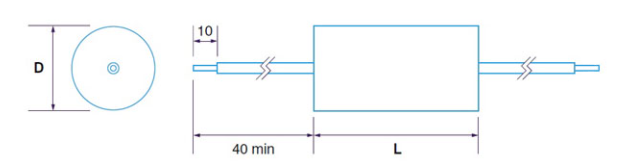

Enhanced Super Audio winding, tape-wrap finish Dimensions in mm

| 250Vdc | 400Vdc | 630Vdc | ||||

| Diameter | Length | Diameter | Length | Diameter | Length | |

| 0.1uF | ||||||

| 0.15uF | ||||||

| 0.22uF | ||||||

| 0.33uF | ||||||

| 0.47uF | 17 | 45 | 20 | 45 | ||

| 0.68uF | 19 | 45 | 23 | 45 | ||

| 1.0uF | 18 | 45 | 22 | 45 | 27 | 45 |

| 1.2uF | 19 | 45 | 24 | 45 | 27 | 45 |

| 1.5uF | 20 | 45 | 27 | 45 | 33 | 45 |

| 1.6uF | 22 | 45 | 28 | 45 | 34 | 45 |

| 1.8uF | 23 | 45 | 29 | 45 | 36 | 45 |

| 2.0uF | 25 | 45 | 31 | 45 | 38 | 45 |

| 2.2uF | 26 | 45 | 32 | 45 | 40 | 45 |

| 2.5uF | 27 | 45 | 34 | 45 | 42 | 45 |

| 2.7uF | 28 | 45 | 35 | 45 | 34 | 50 |

| 3.0uF | 29 | 45 | 38 | 45 | 36 | 50 |

| 3.3uF | 32 | 45 | 40 | 45 | 37 | 50 |

| 3.6uF | 33 | 45 | 41 | 45 | 38 | 50 |

| 3.9uF | 34 | 45 | 33 | 50 | 40 | 50 |

| 4.0uF | 34 | 45 | 34 | 50 | 41 | 50 |

| 4.5uF | 35 | 45 | 36 | 50 | 37 | 60 |

| 4.7uF | 37 | 45 | 36 | 50 | 38 | 60 |

| 5.0uF | 39 | 45 | 37 | 50 | 39 | 60 |

| 5.1uF | 39 | 45 | 38 | 50 | 40 | 60 |

| 5.5uF | 40 | 45 | 39 | 50 | 41 | 60 |

| 5.6uF | 40 | 45 | 40 | 50 | 42 | 60 |

| 6.0uF | 41 | 45 | 41 | 50 | 43 | 60 |

| 6.2uF | 42 | 45 | 42 | 50 | 44 | 60 |

| 6.5uF | 32 | 45 | 36 | 60 | 45 | 60 |

| 6.6uF | 33 | 50 | 37 | 60 | 45 | 60 |

| 6.8uF | 34 | 50 | 38 | 60 | 46 | 60 |

| 7.0uF | 35 | 50 | 38 | 60 | 47 | 60 |

| 7.5uF | 36 | 50 | 39 | 60 | 48 | 60 |

| 8.0uF | 37 | 50 | 41 | 60 | 50 | 60 |

| 8.2uF | 37 | 50 | 42 | 60 | 50 | 60 |

| 8.5uF | 38 | 50 | 43 | 60 | 51 | 60 |

| 9.0uF | 39 | 50 | 44 | 60 | 53 | 60 |

| 10uF | 41 | 50 | 45 | 60 | 55 | 60 |

| 12uF | 45 | 50 | 49 | 60 | 60 | 60 |

| 15uF | 50 | 50 | 55 | 60 | 67 | 60 |

| 18uF | 54 | 50 | 60 | 60 | 73 | 60 |

| 20uF | 56 | 50 | 63 | 60 | ||

| 22uF | 52 | 60 | 66 | 60 | ||

| 25uF | 54 | 60 | 70 | 60 | ||

| 27uF | 56 | 60 | 73 | 60 | ||

| 30uF | 59 | 60 | ||||

| 33uF | 61 | 60 | ||||

| 36uF | 64 | 60 | ||||

| 39uF | 67 | 60 | ||||

| 47uF | 73 | 60 | ||||

PUR Size-Chart 2

Minimum Resonance winding, tape/tube Dimensions in mm

| Tape-Wrapped | Tubed Product | |||

| -S | -ST | |||

| 800Vdc | 800Vdc | |||

| Diameter | Length | Diameter | Length | |

| 0.1uF | 18 | 45 | 38 | 45 |

| 0.1uF | 18 | 45 | 38 | 45 |

| 0.15uF | 22 | 45 | 38 | 45 |

| 0.22uF | 24 | 45 | 38 | 45 |

| 0.33uF | 30 | 45 | 38 | 45 |

| 0.47uF | 35 | 45 | 50.8 | 45 |

| 0.68uF | 42 | 45 | 50.8 | 45 |

| 1.0uF | 29 | 50 | 38 | 50 |

| 1.2uF | 32 | 50 | 50.8 | 50 |

| 1.5uF | 35 | 50 | 50.8 | 50 |

| 1.6uF | 37 | 50 | 50.8 | 50 |

| 1.8uF | 38 | 50 | 50.8 | 50 |

| 2.0uF | 40 | 50 | 50.8 | 50 |

| 2.2uF | 42 | 50 | 50.8 | 50 |

| 2.5uF | 38 | 60 | 50.8 | 60 |

| 2.7uF | 40 | 60 | 50.8 | 60 |

| 3.0uF | 42 | 60 | 50.8 | 60 |

| 3.3uF | 44 | 60 | 50.8 | 60 |

| 3.6uF | 45 | 60 | 76.2 | 60 |

| 3.9uF | 46 | 60 | 76.2 | 60 |

| 4.0uF | 48 | 60 | 76.2 | 60 |

| 4.5uF | 50 | 60 | 76.2 | 60 |

| 4.7uF | 52 | 60 | 76.2 | 60 |

| 5.0uF | 54 | 60 | 76.2 | 60 |

| 5.1uF | 55 | 60 | 76.2 | 60 |

| 5.5uF | 56 | 60 | 76.2 | 60 |

| 5.6uF | 57 | 60 | 76.2 | 60 |

| 6.0uF | 59 | 60 | 76.2 | 60 |

| 6.2uF | 60 | 60 | 76.2 | 60 |

| 6.5uF | 61 | 60 | 76.2 | 60 |

| 6.6uF | 62 | 60 | 76.2 | 60 |

| 6.8uF | 63 | 60 | 76.2 | 60 |

| 7.0uF | 63 | 60 | 76.2 | 60 |

| 7.5uF | 66 | 60 | 76.2 | 60 |

| 8.0uF | 68 | 60 | 76.2 | 60 |

| 8.2uF | 69 | 60 | 76.2 | 60 |

| 8.5uF | 70 | 60 | ||

| 9.0uF | 72 | 60 | ||

| 10uF | 76 | 60 | ||

Component Outline

Ordering Details

Part-number example: PUR 2U2H800V-ST

| PUR | 2U2 | H | 800V | S | T |

| Purity | 2.2uF | ±3% | 800V | MR winding | Acrylic Tube |

Part-number example: PUR 1U0H800V-S

| PUR | 1U0 | H | 800V | S |

| Purity | 1.0uF | ±3% | 800V | MR winding |

Part-number example: PUR 10UH250V

| PUR | 10U | H | 250V |

| Purity | 10uF | ±3% | 250V |